Toxic waste spills have unfortunately become a frequent occurrence throughout our communities. From oil to lead to mercury, there are no positive benefits to toxic spills and no room for error in toxic waste disposal. Often, these spills dangerously alter our ecosystem in ways that could linger for decades, while also endangering the people around it in ways that could affect their health. More specifically in this industry, we deal with toxic materials like adhesives, inks, plastics and protective coating, to name a few, which can cause skin & eye irritation as well respiratory difficulty if not handled properly. And because these materials are used to manufacture packaging needs at a high-volume, it’s very important to be clear and effective with our safety efforts for our employee’s wellbeing. At Bay Cities, we do our part to avoid using dangerous and toxic materials in our warehouses, with just one of many being the adhesives used to seal all our packaging. Potential business partners looking to be more eco-friendly in their production methods can trust us to provide this in a safe and secure manner.

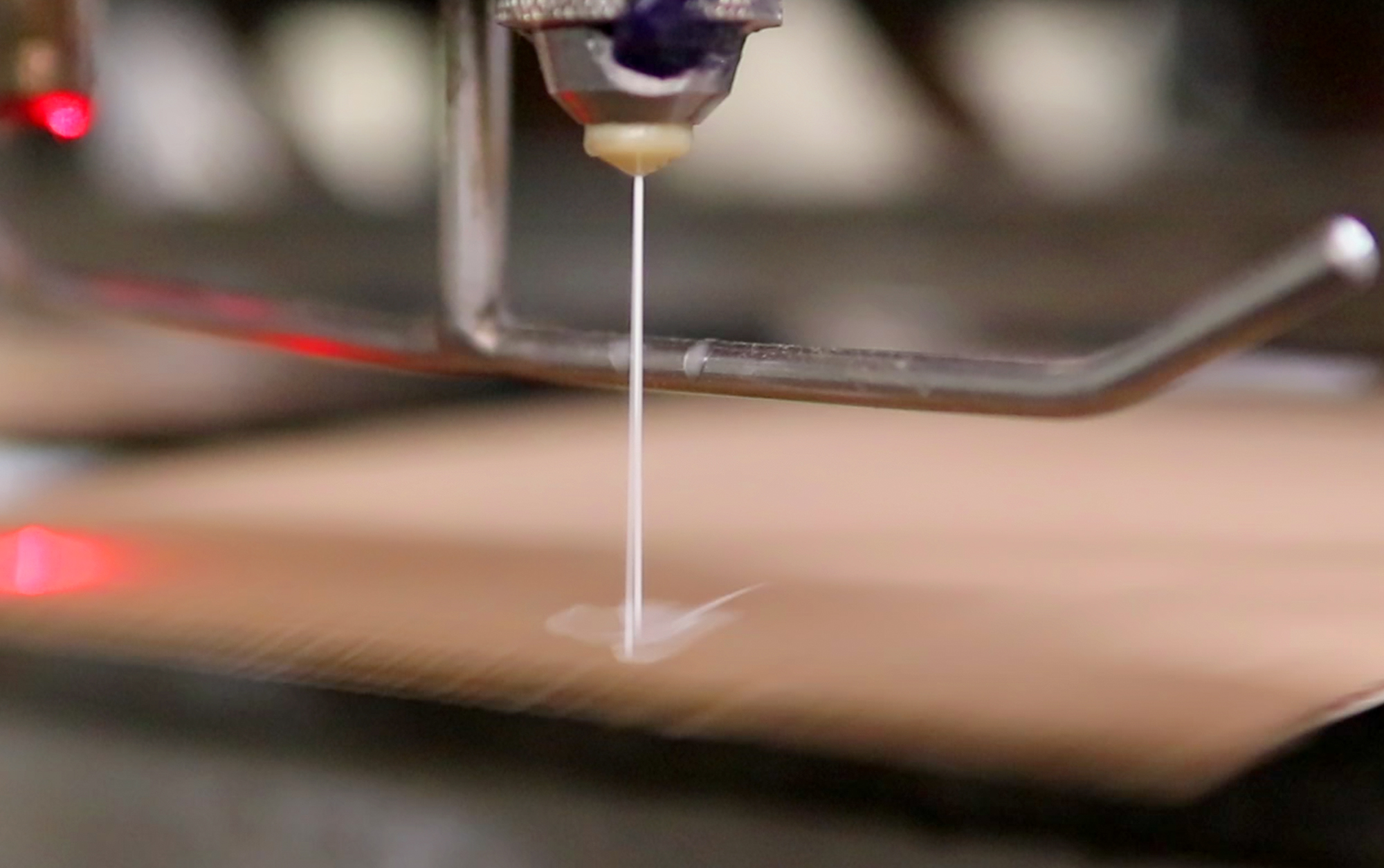

There are several machine stations at Bay Cities that require the usage of adhesives. All eight of the adhesives we use in the process of creating your products are water-based and environmentally friendly, having no negative impact on our ecosystem. Adhesives differentiate based on which machine station they are used at. The machine stations at our facility that require the usage of adhesives include the Roll Coater, ATM, Expert, Emba, Oppliger, Martin and the Post Gluer. If a product is being run by one of these machines, water-based adhesives are in the mix. Water-based adhesives are a sustainable alternative to solvent adhesive as they are formulated from organic, biodegradable polymer. Additionally, our eco-friendly polymer provides a significantly lower cost to use, turning this sustainable practice into a win-win for Bay Cities, our communities, clients, vendors, and ecosystem.

Aside from committing to sustainability because it is our social responsibility, since switching to our water-based adhesives, we have also successfully reduced our overall adhesive consumption. Our machine stations would normally consume 25% more of adhesive per a 10,000-job ticket before the switch. For example, when we look at the Oppliger, we were able to decrease adhesive usage from 30 glue totes, approx. 8,250 gallons (about the volume of a large U-Haul truck) per month, to roughly 20 totes, approx. 5,500 gallons (about twice the volume of a storage unit) per month.

The versatility and efficiency of our adhesives have allowed us to consume less because of the better quality it provides. For example, when the water-based adhesive is applied through the production cycle, it covers more of the corrugate sheet. It spreads easier throughout due to the better manageability of the water base and overall does not dampen the corrugate. In addition, its versatility allows the production process to increase speed. Meaning, since the transition to water based, a heating process is no longer necessary when applying adhesive like it was with solvent based, thus, resulting not only in a quicker production cycle but also less energy consumption.

Although waste is still generated to some extent, we have successfully reduced it and have an environmentally friendly process to reclaim this waste. The generated waste during the production cycle is relocated to a facility where it enters the recycling process. Since it is water based, it goes into recovery or reclamation for reuse, including acid regeneration, organics recovery, etc. After this process, the tote that originally contained the adhesive enters a recycling process as well and renters the consumer cycle. This helps us avoid our waste entering toxic landfills and polluting our ecological system.

This is not the first step nor the last towards our push for a more sustainable Bay Cities. We feel it is our social responsibility to treat our resources with a high grade of respect, so we will continue to pursue and retain procedures and practices that enhance our sustainability initiatives.

/BC_Logo2_White.png?width=300&height=83&name=BC_Logo2_White.png)